Farm trailers

Krampe SK 550 Entreprenørvogn med Hardox kasse SK 500

34 150EUR

- ≈ 3 500 545 INR

- ≈ 39 568 USD

Mi spc 16

29 463EUR

- ≈ 3 020 104 INR

- ≈ 34 138 USD

Mi spc 16

29 463EUR

- ≈ 3 020 104 INR

- ≈ 34 138 USD

Krampe SK 550 Entreprenørvogn med Hardox kasse SK 500

34 150EUR

- ≈ 3 500 545 INR

- ≈ 39 568 USD

Mi Tip SPC18

23 436EUR

- ≈ 2 402 307 INR

- ≈ 27 154 USD

ZNMR-GOLENIÓW TO 70

2 480,04EUR

- ≈ 254 212,4 INR

- ≈ 2 873,52 USD

Siro Vagnen 225 H

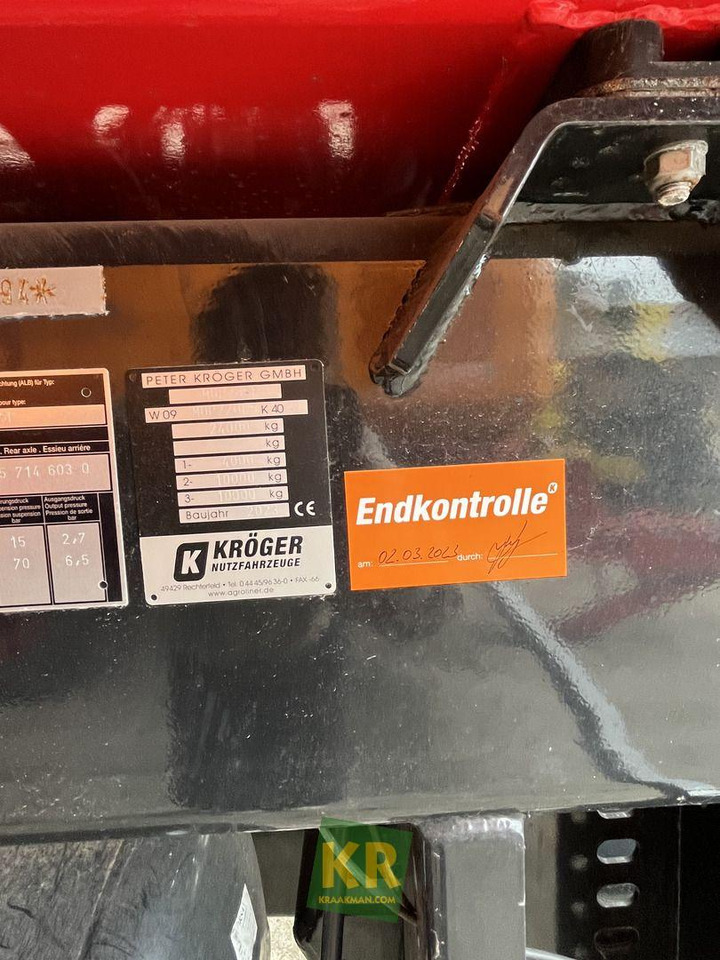

Overig Kröger

Backed by our farming expertise to ensure you get the best value and reliable performance

Kröger Overig

Metsjö Metax bal 61430

11 688EUR

- ≈ 1 198 078 INR

- ≈ 13 542 USD

SLMA 12ton

Velsa 8000 ton

Innovative machines, fast service, and expert support across Italy

JF AV50

Metsjö Metaflex 24T

Röke

RMH VR12

4 million buyers per month search for vehicles and machinery on Truck1.

Francini F60S

Rimorchio usato Schwarz t6057

3 000EUR

- ≈ 307 515 INR

- ≈ 3 476 USD

Di Credico Dumper nuovo DPT 220 S MR

38 700EUR

- ≈ 3 966 943 INR

- ≈ 44 840 USD

GRUAU REMORQUE AGRICOLE G 400

1 600EUR

- ≈ 164 008 INR

- ≈ 1 853 USD

Metsjö MetaQ 60

Twin Axle Tipping Trailer, Hydraulic Tailgate

Agricultural trailers represent essential support equipment for modern farming operations, providing versatile transportation and material handling capabilities that enhance productivity across diverse agricultural activities. These specialized implements enable efficient movement of crops, livestock, equipment, and supplies throughout farm operations while reducing labor requirements and improving operational efficiency. The farm trailers market encompasses various configurations including grain trailers, livestock trailers, flatbed trailers, and specialized equipment trailers designed for specific agricultural applications and load requirements. Modern agricultural operations demand trailers capable of handling substantial payloads while maintaining durability and reliability under challenging field conditions and seasonal usage patterns. The tractor and trailer price range varies significantly based on capacity, construction materials, and specialized features, with basic utility trailers starting around ₹1-3 lakhs and large grain trailers exceeding ₹15 lakhs depending on specifications and manufacturer reputation. Professional farming operations increasingly utilize sophisticated trailers featuring hydraulic systems, automated controls, and specialized loading mechanisms that maximize efficiency while reducing manual labor requirements and improving safety during material handling operations.

Types and Classifications of Agricultural Trailers

Grain trailers represent the largest category of agricultural trailers, designed for efficient transport of harvested crops from fields to storage facilities or markets. These trailers feature high-capacity bodies with smooth interior surfaces, waterproof construction, and efficient unloading systems that preserve grain quality during transport. Capacities typically range from 8-25 tonnes, with larger units featuring tandem or tridem axle configurations that distribute weight while maintaining road legal compliance. Advanced models incorporate hydraulic tilting systems, conveyor unloading, and integrated tarp systems that protect loads from weather exposure.

Livestock trailers provide safe, comfortable transportation for cattle, sheep, pigs, and other farm animals between facilities, markets, and grazing areas. These specialized trailers feature ventilation systems, non-slip flooring, partition gates, and loading ramps designed for animal welfare and handler safety. Capacities range from small single-axle units accommodating 6-8 cattle to large tri-axle trailers handling 25-30 head. Modern livestock trailers incorporate aluminum construction for corrosion resistance, hydraulic loading systems, and monitoring equipment that ensures animal comfort during transport.

Flatbed and utility trailers offer maximum versatility for transporting equipment, building materials, baled hay, and miscellaneous farm supplies. These trailers feature reinforced decks, removable sides, and tie-down systems that accommodate diverse loading requirements. Standard widths range from 2.4-3.0 meters with lengths extending to 12+ meters for specialized applications. Heavy-duty models feature hydraulic tilting capability for easy loading and unloading of equipment and materials.

Specialized trailers include silage trailers with reinforced construction for heavy, dense loads, manure spreaders with integrated application systems, and equipment trailers designed for specific implements. Tank trailers transport liquid fertilizers, water, and fuel with specialized pumping and dispensing systems. These specialized units command premium pricing due to limited production volumes and application-specific engineering requirements.

Self-loading trailers incorporate lifting mechanisms, conveyors, or hydraulic systems that enable autonomous loading without external equipment. These sophisticated units maximize labor efficiency while reducing dependency on loading equipment availability, particularly valuable for operations with limited equipment or labor resources.

Technical Specifications and Performance Features

Modern agricultural trailers incorporate advanced engineering to optimize payload capacity while maintaining structural integrity and road compliance. Chassis construction utilizes high-strength steel with reinforced stress points designed for continuous heavy-duty operation. Load ratings typically range from 5-30 tonnes depending on axle configuration and intended application, with gross vehicle weight ratings (GVWR) carefully matched to towing vehicle capacity and legal requirements.

Axle systems vary from single-axle configurations for light utility applications to tri-axle designs for maximum capacity grain trailers. Suspension systems include leaf springs for durability and low maintenance, air suspension for ride quality and load protection, and walking beam designs for rough terrain capability. Brake systems feature electric or hydraulic actuation with load-proportioning valves that ensure safe stopping performance across varying load conditions.

Hydraulic systems provide power for tilting, gate operation, and specialized functions including conveyor drives and loading mechanisms. These systems typically operate at 2,000-3,000 PSI pressures with flow rates optimized for application requirements. Advanced trailers feature load-sensing systems that automatically adjust hydraulic performance based on load weight and operating conditions.

Tires and wheels represent critical components affecting performance, fuel economy, and road impact. Tire sizes range from 11R22.5 for lighter applications to 445/65R22.5 for heavy-duty service, with specialized agricultural tires offering enhanced traction and flotation for field operations. Wheel materials include steel for durability and cost-effectiveness, while aluminum wheels provide weight savings and corrosion resistance at premium pricing.

Electronic systems include LED lighting for visibility and compliance, electronic brake controls for integration with modern tractors, and monitoring systems that track load weight, tire pressure, and hydraulic performance. Advanced units feature GPS tracking and telematics systems that provide location monitoring and utilization data for fleet management applications.

Applications Across Different Agricultural Operations

Grain farming operations utilize high-capacity trailers for efficient harvest transport from combines to storage facilities or markets. These applications demand rapid loading and unloading capabilities to minimize combine downtime during critical harvest periods. Grain trailers with conveyor unloading systems can discharge 20-tonne loads in 10-15 minutes, significantly faster than gravity-fed designs. Seasonal utilization may be limited to harvest periods, requiring cost-effective solutions that justify investment through increased harvest efficiency.

Livestock operations require trailers designed for animal welfare, handler safety, and regulatory compliance. Cattle trailers must accommodate various animal sizes while providing adequate ventilation, secure containment, and stress-free loading environments. Modern livestock trailers feature hydraulic decks that adjust to loading dock heights, reducing animal stress and improving loading efficiency. Specialized designs include horse trailers with individual stalls and climate control systems for high-value animals.

Mixed farming operations benefit from versatile trailers capable of handling diverse materials and applications. Convertible designs enable rapid reconfiguration between grain hauling, equipment transport, and general cargo applications. These trailers typically feature removable sides, adjustable decks, and modular loading systems that adapt to seasonal requirements without requiring multiple specialized units.

Commercial farming and agribusiness operations utilize large-capacity trailers optimized for specific commodities and handling systems. Sugar beet trailers feature specialized unloading systems for processing facilities, while cotton trailers accommodate module handling systems. These specialized applications often justify premium equipment investments through improved handling efficiency and reduced product damage.

Custom farming and contractor operations require durable, versatile trailers capable of handling diverse clients and applications. These operations often utilize standardized trailer designs that maximize parts commonality while providing flexibility for various crop types and field conditions. Efficient loading and unloading systems minimize turnaround time, critical for maintaining productivity across multiple client operations.

Economic Analysis and Investment Considerations

Agricultural trailers pricing structures reflect capacity, construction quality, and specialized features designed for specific applications. Basic utility trailers start around ₹1-3 lakhs for single-axle units, while mid-range grain trailers typically cost ₹5-10 lakhs depending on capacity and features. Large, specialized trailers with advanced hydraulic systems and automated controls can exceed ₹15 lakhs, requiring careful analysis of productivity benefits and operational efficiency improvements.

Operating costs include maintenance, repairs, tires, and registration fees, typically averaging 8-12% of purchase price annually. Tire replacement represents a significant expense, with complete sets costing ₹80,000-2 lakhs depending on size and quality. Hydraulic system maintenance requires specialized knowledge and tools, while structural repairs may demand welding capabilities and heavy equipment access.

Productivity improvements justify trailer investments through reduced labor requirements, faster loading cycles, and improved material handling efficiency. Modern grain trailers with conveyor unloading can reduce unloading time by 60-80% compared to gravity systems, enabling more loads per day during critical harvest periods. Labor savings of 1-2 hours per load can justify premium features through reduced wage costs and improved operational efficiency.

Utilization analysis must consider seasonal usage patterns and multi-purpose applications that maximize return on investment. Grain trailers may see intensive use during 2-3 month harvest periods but remain idle during other times, while utility trailers provide year-round versatility across diverse applications. Multi-purpose designs enable better utilization but may compromise specialized performance in specific applications.

Used trailer markets provide cost-effective alternatives, with 5-7 year old units typically priced at 40-60% of new values depending on condition and maintenance history. However, structural integrity, hydraulic system condition, and remaining service life must be carefully evaluated. The tractor and trailer price range in used markets offers opportunities for operations with limited budgets but requires thorough inspection and potential reconditioning investments.

Selection Criteria and Operational Optimization

Payload requirements represent the primary selection criterion, with trailer capacity closely matched to typical load sizes and towing vehicle capabilities. Overloading reduces component life and creates safety hazards, while underutilized capacity increases cost per tonne transported. The farm trailers selection should accommodate maximum anticipated loads while maintaining legal weight compliance and tractor compatibility.

Towing vehicle compatibility encompasses power requirements, hydraulic capacity, electrical systems, and hitching arrangements. Larger trailers require tractors with adequate power reserves for maintaining productivity, while hydraulic functions demand sufficient flow and pressure capability. Electrical compatibility ensures proper lighting and brake operation, while hitch ratings must exceed trailer gross weights with appropriate safety margins.

Application versatility influences trailer configuration and feature selection. Single-purpose trailers optimize performance for specific applications but limit utilization opportunities, while multi-purpose designs provide flexibility at potential performance compromises. Seasonal farming operations often benefit from convertible designs that adapt to changing requirements throughout the crop cycle.

Operating environment considerations include road conditions, field access, storage facilities, and regulatory requirements. Rough field conditions favor reinforced construction and enhanced suspension systems, while highway operation emphasizes aerodynamics and fuel efficiency. Storage facility compatibility affects trailer dimensions and unloading system selection, while local regulations influence weight limits and equipment requirements.

Maintenance capabilities and service support availability significantly impact long-term ownership satisfaction. Complex hydraulic systems require specialized knowledge and tools, while basic mechanical trailers enable on-farm maintenance and repairs. Local dealer networks provide parts availability and technical support, particularly important for operations in remote locations or with limited technical resources.

Safety and Regulatory Compliance

Transportation safety requires comprehensive attention to braking systems, lighting, weight distribution, and load securement. Modern agricultural trailers feature integrated brake systems that coordinate with tractor controls, while independent emergency braking provides safety backup in case of coupling failure. Proper weight distribution prevents trailer sway and maintains steering control, critical for safe highway operation with heavy loads.

Load securement systems must comply with transportation regulations while accommodating diverse cargo types and loading conditions. Grain trailers require waterproof covers and secure latching systems, while equipment trailers need comprehensive tie-down systems and blocking arrangements. Livestock trailers demand specialized gates, ventilation systems, and emergency access provisions that ensure animal welfare during transport.

Regulatory compliance encompasses weight limits, dimension restrictions, lighting requirements, and registration procedures. Maximum legal weights vary by jurisdiction and road classification, requiring understanding of applicable regulations and route planning. Commercial operations may require additional permits, inspections, and documentation that affect operational procedures and costs.

Maintenance safety includes proper lifting procedures, hydraulic system precautions, and electrical safety measures. Hydraulic systems operate under high pressure and require specialized tools and procedures for safe maintenance. Electrical systems must accommodate harsh agricultural environments while maintaining safety and reliability standards.

Operator training ensures safe operation, proper loading procedures, and regulatory compliance. Training programs should cover pre-trip inspections, load distribution principles, backing techniques, and emergency procedures. Documentation of training and certification may be required for commercial operations or insurance compliance.

What factors determine the tractor and trailer price range for different agricultural applications?

Tractor and trailer price range depends on capacity, construction materials, specialized features, and intended applications. Basic utility trailers start around ₹1-3 lakhs for single-axle units, while mid-range grain trailers cost ₹5-10 lakhs, and large specialized trailers with hydraulic systems can exceed ₹15 lakhs. Key price factors include payload capacity (5-30 tonnes), axle configuration, hydraulic systems, construction materials (steel vs. aluminum), and specialized features like conveyor unloading or livestock handling equipment.

How do different agricultural trailers compare in terms of versatility and specialized performance?

Grain trailers offer high capacity and efficient unloading for crop transport but limited versatility, while flatbed trailers provide maximum flexibility for diverse loads but may require additional securing equipment. Livestock trailers optimize animal welfare and safety but serve single-purpose applications. Self-loading trailers maximize labor efficiency but cost 30-50% more than conventional designs. Multi-purpose trailers with removable sides and convertible features provide good versatility but may compromise specialized performance compared to dedicated designs.

What are the typical operating costs and maintenance requirements for farm trailers?

Annual operating costs average 8-12% of purchase price, including maintenance, repairs, tires, and registration. Tire replacement represents major expenses of ₹80,000-2 lakhs per set every 3-5 years depending on usage and conditions. Hydraulic system maintenance requires specialized service every 1,000-2,000 hours, while structural maintenance includes welding, bearing replacement, and brake service. Daily maintenance involves grease lubrication, tire pressure checks, and safety inspections to prevent costly failures and ensure regulatory compliance.

How do payload capacity and axle configurations affect trailer selection and performance?

Payload capacity should match typical load requirements while maintaining legal weight compliance and tractor compatibility. Single-axle trailers suit loads up to 8-10 tonnes, tandem axles handle 15-20 tonnes, while tri-axle configurations accommodate 25-30 tonnes. Axle configuration affects weight distribution, ride quality, and road impact. Overloading reduces component life and creates safety hazards, while underutilized capacity increases transport costs. Proper axle selection optimizes tire wear, fuel efficiency, and structural longevity.

What hydraulic and automated features provide the best return on investment for agricultural trailers?

Hydraulic tilting systems reduce unloading time by 50-75% and justify costs through labor savings and improved productivity. Conveyor unloading systems can discharge 20-tonne loads in 10-15 minutes compared to 30-45 minutes for gravity systems. Automated tarp systems add ₹1-2 lakhs but provide weather protection and regulatory compliance. Self-loading mechanisms eliminate dependency on external loading equipment but require 30-50% higher investment. ROI typically achieves payback in 2-4 years for operations with regular high-volume usage.

How do seasonal usage patterns affect agricultural trailer selection and economics?

Seasonal utilization significantly impacts trailer economics, with grain trailers seeing intensive 2-3 month harvest usage but remaining idle other times. Multi-purpose designs improve utilization but may compromise specialized performance. Operations with diverse seasonal activities benefit from convertible trailers that adapt to changing requirements. Seasonal contractors may justify premium equipment through intensive usage, while limited-use operations favor simpler, cost-effective designs. Economic analysis should consider annual utilization hours and alternative applications during off-seasons.

What safety features and regulatory requirements are essential for agricultural trailer operation?

Essential safety features include integrated brake systems with emergency backup, proper lighting systems, load securement equipment, and weight distribution optimization. Regulatory requirements include maximum weight limits, dimension restrictions, lighting compliance, and registration procedures. Livestock trailers require ventilation systems, emergency access, and animal welfare provisions. Commercial operations need additional permits and inspections. Safety training covers pre-trip inspections, load distribution, backing techniques, and emergency procedures essential for safe highway and field operation.

How do used agricultural trailers compare to new equipment in terms of value and reliability?

Used agricultural trailers typically cost 40-60% of new prices after 5-7 years, providing significant cost savings for budget-conscious operations. However, buyers must evaluate structural integrity, hydraulic system condition, tire wear, and remaining service life. Well-maintained trailers from reputable manufacturers often provide excellent value, while heavily-used or poorly-maintained units may require substantial reconditioning. Inspection should include frame examination, brake testing, hydraulic performance evaluation, and electrical system verification to ensure reliable, safe operation.

What are the key considerations for matching trailers to tractor capabilities and farm operations?

Tractor matching requires adequate power reserves, hydraulic capacity, electrical compatibility, and appropriate hitch ratings. Tractors should provide 20-30% power reserve above trailer requirements for maintaining productivity on hills and in adverse conditions. Hydraulic capacity must support trailer functions while maintaining tractor operation. Electrical systems need compatible voltage and current capacity for lighting and brake operation. Farm operations should consider field access, storage facilities, loading equipment availability, and seasonal workflow integration when selecting trailer configurations.

How do financing options and ownership alternatives compare for agricultural trailer investments?

Financing options include traditional equipment loans (8-12% interest, 5-7 year terms), manufacturer programs, and lease arrangements. Operating leases provide tax advantages and upgrade flexibility but higher long-term costs. Finance leases offer ownership benefits with lower monthly payments than purchase financing. Used equipment financing typically requires higher down payments and shorter terms but enables access to proven equipment at lower costs. Government subsidies may provide 25-40% assistance for qualifying operations, significantly improving investment economics for eligible buyers.